Working with wood and other materials can be time consuming and require a lot of skill. Of course, there are certain tools and accessories that just might help you when you’re working on projects. One such tool is the drill press vise.

Drill press vises have a very simple job and that is to hold your items in place while you work. No slipping or struggling to keep materials sturdy while you work. Just grab your best drill press vises and put them to work! You will find that this makes your job so much easier, especially for reaming, counter sinking, multiple holes boring, and other similar tasks.

In this guide, we will share with you the best drill press vises on the market. We’ve got all of the information you need from things to consider, detailed reviews, a complete buyer’s guide, and even some FAQ for you. We’ve searched the market to try to find the very best options and we think you will be happy with these choices as well.

Table of Contents

How to Choose the Best Drill Press Vises

Before you set out to find a drill press vise, it’s a good idea to familiarize yourself with the details and figure out just what you might need – or at least know the basics to look for. In this part of our guide, we break it down by providing you with the details of specific things to keep in mind to choose the best drill press vise for your needs.

Drill Press Vise Vs. Clamps

You may hear people tell you to just use a clamp that you have on hand instead of investing in drill press vises. That recommendation is all well and good but let’s talk about the differences so you can choose for yourself.

Here’s the thing, a clamp is made to clamp things together, as is a vise. Clamps come in different styles and types. They also come in different sizes. Your drill press table might even have mounting slots for a clamp in it.

However, drill press vises were made specifically to be used with drill presses. When it comes down to it, a drill press vise is more suitable for most jobs where drill presses are concerned, since they were made for that purpose.

A drill press vise will better conform to drill presses or a drill press table and it will have the ability to hold the materials more securely. You get far more control using a press vise with your drill press machine as opposed to using a clamp.

If clamps are what you have on hand, these will most likely work for small jobs but when you need precision and control, plan to use a vise with your drill press machine for the best results.

Drill Press Type

There is more than one type of drill press but there are only two main kinds. This really is just the way the drill press vise is constructed overall. Within these categories, there are still different styles.

The two main types are as follows:

- Quick Release: a quick release model is considered to be easy to use and you can easily readjust it as needed. These are the most popular because you can just use a button to move or adjust your press.

- Tilting: The tilting drill press vise attaches with the jaws but then the head tilts to different angles. These are great for round materials and might even have vertical and horizontal grooves for you to work with.

Within those two main categories, you will still see different choices to make as well. For example, you may have to choose between a cross slide drill press vise or maybe a flat press vise.

The cross slide drill press vise offers a little more versatility as you can slide it over a larger span of material. These usually last a little bit longer because of the sliding feature. These are often tilting but you might find them as a quick release as well.

The flat drill press vise is best for light duty tasks and it is a common choice for quick release models. They have good clamping pressure but are more simplified and could potentially be more limited.

The thing you need to be aware of is that these drill press vises aren’t always a one size fits all and some vises jaws are made for specific uses. Be sure you get a press vise that is going to work with your drilling operations as well as whatever drill press machines you might be using.

Throat Depth

One thing you will want to keep in mind about your drill press vise is the throat depth measurement. Ultimately, this is the measurement of the jaw width from the very top of the jaw clear down to the tip of the vase. It lets you know just how much room you have to work with and how deep your jaw can be placed.

This will be important primarily if you work with large projects or maybe if you are working with something irregular on your drill press machines. Otherwise, it may not matter most of the time.

Drill Press Vise Jaws

The last detail we are going to bring up here is the drill press vise jaws. Different jaws might give you different results when you’re working so that is something to keep in mind. You will find that some jaws might have texture or etching on them.

That texturing helps when you need a good grip on a slippery material. A vise without texture or etching might just slide right off of slippery wood and metal if you aren’t careful. Basically, these jaws will give you extra grip compared to a jaw with no etching on it.

Sometimes, the grip is the most important element of this tool. This may not be an issue for you but if you want something that will always have a steady grip, we recommend just choosing a drill press vise with texture/etching to make that happen.

When you consider hardened v grooved jaws, the biggest difference is the grip security, particularly on slick materials.

We Think You’ll Like It: Best Drill Press for Metal

The Best Drill Press Vises On the Market

It’s time to get down to business. You know your drilling operations the best, as well as what your drill presses might need. Take these tips and your needs and pair them up as you take a look at the drill press vise options that we’ve selected for you here.

We did our best to sort through the options and really narrow it down to the very best. We made every effort to bring a variety of choices for people to look through and we hope we found something that will work for you here.

1. Best Overall: Irwin Tools Drill Press Vise

First up is our best overall choice, the Irwin Tools drill press vice. This vice has really awesome clamping force thanks to the grooved jaws. It is a cross slide vise and Irwin Tools did a really great job on the overall design compared to come different drill press vises out there. Accurate drilling shouldn’t be a problem here.

This vice comes with four mounting slots so you can secure it to your drill press table with easy installation and get easy and accurate drilling as well. It’s lightweight but also made with heavy duty construction. The primary material is forged iron so this cast iron drill press vise is built to last.

This is a 4 inch drill press vise. It has a jaw capacity of 4.5 inches so it can be used for a variety of things, particularly smaller projects as well as small round objects. The Irwin model is compatible with several different drill press machines.

The blue powder coat finish really makes it look nice but looks aren’t everything. The real draw to this little tool is the security it gives you during the drilling process, the durable cast iron build, and the textured jaws to hold workpieces securely and tightly so you can get precise holes each time.

Specs:

| Jaw Allowance: | 4.5 inches |

| Vise Type: | Cross slide |

| Construction materials: | cast iron |

| Mounting Holes: | 4 |

| Size: | 4 Inches |

Key Features: (On a scale of 1-10 with 10 being the highest)

- Jaw Capacity: 10

- Grip: 10

- Durability: 10

- Mounting: 10

- Versatility: 8

- Four mounting bolt holes

- Rest assured this is built with quality materials

- Textured jaws give you a solid grip

- Reasonable clamping capacity

- Easy to install and position to drill holes

- Some users mention that this sometimes has sharp edges

Why We Like It: This vice is great for keeping it simple, particularly if you need something portable and easy to attach and adjust. It has a firm grip so you can enjoy precise drilling. The slotted base makes mounting easy on this 4 inch drill press vise

2. Budget Pick: Yost Tools 4 Inch Light Duty Drill Press

This next option is very similar to the Irwin choice we just shared but it is a budget-friendly version. While it’s affordable, it isn’t cheaply made so you can rely on this to be a great cross slide vise grip tool when you need it. The jaw capacity is 4 inches with a throat depth of .85 inches. It’s lightweight and very portable but still made with solid cast iron and chrome plated steel.

Yost Tools drill press vice has a slotted base with 4 slots that allow you to easily position it and attach it wherever you need to. The jaws are textured so your grip will be secure no matter what your materials are. You can even use this on round shaped objects, although it isn’t a tilting option.

This is a light duty drill press so while it has a strong grip, it’s not meant for really intense jobs. If you know and understand that it does have limitations, you will be completely happy with it.

The drill press vise measures about 4 inches in length and your jaw allowance is 4 inches wide with a throat depth of .95 inches as well. This gives you a standard amount of working room with the vise so you should be set.

Specs:

| Jaw Allowance: | 4 inches |

| Vise type: | Cross slide |

| Construction materials: | cast iron |

| Mounting Holes: | 4 |

| Size: | 4 Inches |

Key Features: (On a scale of 1-10 with 10 being the highest)

- Jaw Capacity: 10

- Grip: 9

- Durability: 10

- Mounting: 10

- Versatility: 8

- Budget-friendly drill press vice

- Simple construction that you can depend on

- Easy to mount onto your drill press

- Made with durable materials

- Textured jaws for a steady grip

- The surfaces are not deburred, making them sharp so use with caution

Why We Like It: Cast iron construction and a decent jaw width give you a great tool for light duty tasks here. It’s simple but effective and it has a strong, reliable grip. The best part is that it’s made to be affordable and it works for simple projects with that design.

3. Best Value: Shop Fox D4082 Cross Slide Drill Press Vise

If you’re looking for the best bang for your buck, take a quick glance at this Shop Fox model. It’s great for all drill presses and this cross slide drill press vise has angled capabilities for you as well. The jaw width is 4 inches and the capacity is also 4 inches. It’s a heavy duty cast iron construction press vise that works with most drill presses.

This is great for work with a milling machine or milling jobs. It’s solid and sturdy and the jaw pads are smooth so that is something to be aware of. You can work with round objects and expect precision ground results in the end.

This is made with forged iron cast iron and even has cold rolled steel screws in the design. It has solid mounting holes on each side to hold the 23 pounds of weight it comes in. The jaw capacity is good, as is the overall size. It’s big and reliable and made with sturdy materials.

These drill press vises are from a well-known brand in the tool industry. You can use this with a Shop Fox drill press or just with any drill press that you happen to have. It’s a quality solution and a good value for the money considering the possibilities.

Specs:

| Jaw Allowance: | 4 inches |

| Vise type: | Cross slide |

| Construction materials: | cast iron |

| Mounting Holes: | multiple |

| Size: | 5 1/4 Inches |

Key Features: (On a scale of 1-10 with 10 being the highest)

- Jaw Capacity: 10

- Grip: 9

- Durability: 10

- Mounting: 10

- Versatility: 10

- Cast iron construction gives you a durable drill press vise

- Large-scale operation with 4 inch slide travel

- The throat depth is deep at 3 3/4 inches

- Drill press vice is easy to mount to your machine

- Great for light milling jobs and keyways

- This comes pretty rough considering the price. It will need to be cleaned and spots might need to be filed as well

Why We Like It: This is a great value for the money. It works well for milling operations as well as other uses. You can rely on precise positioning and a durable build thanks to iron and cold rolled steel screws. These drill press vises are simple but reliable.

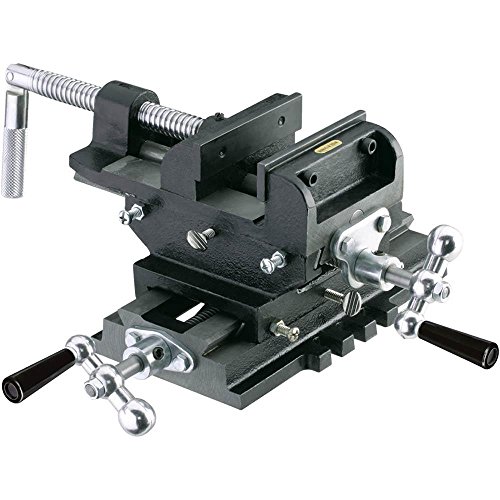

4. Hardware Factory Store 2-Way Drill Press

This next option is another simple option. Hardware Factory is affordable and it is well-made. You can purchase it in different sizes depending on what your needs are. This is another large piece with a good throat depth as well as a great jaw size. The tool itself is 3, 4, f, or 6 inches but 4 is the standard build compared to most drill press vises on the market.

As most drill press vises are, this is made with durable cast iron. The jaws are very strong and made with serrated steel so they are grooved jaws. This is a large piece with cast iron castings rather than a slotted base for attachment to your drill press.

This hinged tilting vise brings you large capacity jaws that are steel jaws. The pivot handle easily cranks to adjust the vise but also hinges so it can drop out of the way. This allows for cross travel so you have a lot of options when it comes to your drilling process.

With easy installation and plenty of size and space, you really can’t go wrong here. It’s a budget-friendly design that you can depend on to give you quality and durability.

Specs:

| Jaw Allowance: | 4 inches |

| Vise Type: | Cross slide |

| Construction materials: | cast iron |

| Mounting Holes: | multiple bolt slots |

| Size: | 5 Inches |

Key Features: (On a scale of 1-10 with 10 being the highest)

- Jaw Capacity: 10

- Grip: 10

- Durability: 10

- Mounting: 10

- Versatility: 10

- Includes 2 swivel handles that can be adjusted or hinged out of the way

- 3.5 inch throat opening

- Great for woodworking and metal working of all kinds

- Bolting holes for easy installation

- Affordable vise for a drill press

- As with many other drill press vice options, you will need to clean this one up and oil it for those rough edges and spaces

Why We Like It: Quality cast iron, hardened steel screws, adjustable handles, what more could you really need? Considering the price of this tool, you really get a very nice drill press vice. It’s sturdy, solid, and made to do all kinds of work!

5. Wilton Tools 11746 6-Inch Low Profile Drill Press Vise

This next option is a premium model that is comparable to the old Delta drill press vise style that is so hard to find. Wilson Tools does cost a little bit more but the design and the build are well worth it. It’s a 6-inch model and it’s also low profile so why you do have larger jaws, you still have a small and portable clamping device that you can depend on here.

This tool sports V grooves that are both vertical and horizontal to give you the best grip around. The jaws are also made with hardened steel. Each side has 2 shoulder slots so that you can mount it to your drill press easily and move it around to adjust it however you need to.

The sliding piece is made with an acme threaded screw that is coated in black oxide. Everything on this tool is of exceptional quality, which is why it costs just a little bit more. It’s also made to be versatile so it comes in handy for drilling, tapping, reaming, and more.

On the same note, this is made to be low profile so it is compact and it is easily portable. It’s secure and your materials are not going anywhere when they are held in these jaws.

Specs:

| Jaw Allowance: | 6 inches |

| Vise Type: | Cross slide |

| Construction materials: | cast iron |

| Mounting Holes: | 4 slots |

| Size: | 8.5 Inches |

Key Features: (On a scale of 1-10 with 10 being the highest)

- Jaw Capacity: 10

- Grip: 10

- Durability: 10

- Mounting: 10

- Versatility: 10

- Made to be a premium model

- High-quality materials on every part of the tool

- Drill press vise is made with cast iron

- Hardened grooves that go both vertical and horizontal

- Compact, low profile design

- Some buyers had issues with the jaws not matching on their drill press vise

Why We Like It: This model comes at a premium because it is made to be premium. We really like the low profile design as well as the extra strength grip thanks to those grooves in the jaws. You don’t even have to clean this one up to get rid of sharp grooves and grit to use it.

Buyer’s Guide

You’ve seen all of our top picks now so let’s turn our focus to important elements about your drill press vise. If you really want to get the best for yourself, there are several things that you need to keep in mind before you make an official purchase.

That’s what this part of our guide is all about.

How Does a Drill Press Vise Work?

If you’re going to use this tool, it’s important that you understand how it works so you know when it will actually be beneficial to you.

Each drill press is made up of varying parts but there are 3 specific parts that will make a significant difference when you use the vise. These come in all sorts of shapes, sizes, and options so what you are using it for very well might affect how you use it as well as what you need.

The drill press vise almost always is mounted onto a flat base that you can mount to your press table. Most of them include mounting holes or mounting slots and this is something you want to watch for. These should line up with the mounting holes on your drill press for connective purposes.

Those are your two main components. You have the base and you have the mounting structure. The other component, which just might be the most important, is the jaws of the vise. The jaws are what are really going to do the work but you have to have a sturdy base that is mounted properly in order to use the vise jaws for that purpose.

When to Use a Drill Press Vise

You can use a vise any time that you are doing a project on your drill press. It’s really that simple. However, you should use a vise any time that precision and accuracy are important or anytime that you are doing a large or repetitive project.

A vise is similar to a clamp, as we discussed earlier. However, a vise will have a more secure grip in this case because that is what it was designed for. Using a vise can help hold your materials secure but it also will most likely keep your drill from locking up from jamming.

This is because the materials are secure so they aren’t going to slide under the pressure of the vise. You may not always need a vise but it does make a difference in precision and workability. It also will probably make things so much easier for you if you just give it the chance.

We Think You’ll Like: How to Attach a Vise to a Drill Press

Type of Drill Press

Something that you may need to consider is the type of drill press that you have. Most drill presses are upright but there are some that are a radial arm drill press and work horizontally instead. We’re going to operate on the assumption that you probably have an upright press but we also know that not everyone does.

When it comes to choosing press vises, just be sure that they are compatible with the press that you have. You need to make sure they are going to fit and that they are going to work on the press or else you’re just wasting your time and your money here.

The good news is that most press vises will work for any type of machine. They are typically made to be universal with mounts that will work on just about any machine. You just might need to double check to be on the safe side.

Size

The size of those steel jaws matters as well. The standard size is 4 inches but it is possible to find them in other sizes as well.

In this case, we’re talking about the spread of the jaw but it’s also a good idea to pay attention to the depth of the jaw so you know what kind of materials or work your tool can handle when you get it set up.

You will find that the jaw depths vary a lot from tool to tool. There is really no standard but you should consider your projects and the types of materials that you work with so that you know you’re choosing a press vise that is really going to work for what you need it to do for you.

Installation

Installation is a part of every drill press vise but the key factor is whether or not the vise is easy or really hard to install. Most of them have something like a vertical t slot or possibly drilling and mounting holes to attach them. That is not always the case.

You will find that all of the options we shared here are designed to be easy to install. This was a quality we felt was really important for everyone so it’s something we made a point to look for.

You want to be able to install easily but you also want to be able to make adjustments and move your vise easily if it is necessary for your task. Take a look at these details so you know that you can install and adjust as needed.

Versatility

Finally, different vises might be made for different things. Some of them are made to be versatile and work for a variety of tasks but others are made to be specialized. This is a detail that you should plan to pay attention to.

If you have a specific task, that’s great! Just make sure that your vise can handle it. If you want something that is multi-functional then look for that quality. Most of the vises out there will tell you if they work best for certain qualities.

You might see recommendations like angled drilling, reaming, keyways, and more. There are plenty of tasks and some of these are made to be more universal while others might be specialized.

Frequently Asked Questions

What Accessories Do I Need Besides a Vise?

It really depends on what it is you are doing as to what you might need. A vise is among one of the most important tools that you can invest in. If you’re looking for some other useful accessories, consider a larger table, T-tracks, V-blocks, and maybe even applicators for cutting fluid. Just leave the vise at the top of your list.

Can I Use Regular Clamps Instead of a Vise?

You can but if you want the strongest hold, a vise is recommended. A clamp will hold but it may be limited as to the strength of its hold and you could still experience slippage. Vises are made for just this task on a drill press and they give you a secure grip that probably isn’t going anywhere.

Which Type of Drill Press Vise Should I Use?

It really depends on what you need and what you are doing. A regular vise will be the most universal but it could certainly have some limitations. A cross slide allows you a little more versatility and the ability to make adjustments on a sliding scale. The tilting type tilts and angles so you can move it where you need it for the task.

Conclusion

We hope that this guide to the best drill press vise proves to be a valuable resource for you. There are some really great options out there. We worked to bring you the very best but still bring you a variety of options to choose from. Always remember to keep your needs in mind when you make a choice.

Expert Tip

Always check the depth of the jaws to make sure that this will accommodate your needs. Some of them will open wide but have very little depth to work with.

Did You Know?

Did you know that a vise is much better than a clamp when it comes to using it with the drill press? Those jaws securely lock onto the materials to actually keep them in place without sliding and slipping. Most users experience less slipping, which leads to less jamming when they are drilling.

We Think You’ll Like: Best Drill Press Under 500 in 2022 – Reviews & Buyers Guide

Amazon Recommends:

- Slotted base for easy installation and positioning

- Textured jaws for secure gripping

- 4.5 Inch jaw capacity perfect for light duty tasks

- Lightweight and portable

- Crated of forged iron for long-lasting durability

- Grip woods, metals, plastics and more

- Cast iron construction provides stability to drilling operations

- 3 in. jaws open up to 3-1/10 in. with a 1 in. throat depth

- Includes 4 onboard mounting slots to securely fasten the vise to a drill press table

- Universal design compatible with the majority of drill presses on the market (see images for base dimensions)

- 3.25 by 1.25 in. jaws open up to 3.25 in. wide

- Constructed of industrial-strength powder-coated cast iron

- Hand wheels feature machine-marked 0.1 mm increments for maximum precision

- Jaws travel 5.8 in. left and right and 6 in. front and back

- Universal design compatible with the majority of drill presses on the market (see images for base dimensions)