In the industry of power tools, many tools are made specifically for wood or specifically for metal and then there are tools that are made to handle both. When it comes to a lathe, there are both wood lathes and metal lathes.

So, what’s the difference?

In this guide, we will walk you through what the differences are between wood lathes and metal lathes so you have a complete understanding of each one and how they vary. Our goal is simply to help you understand just how these tools differ so you know what is suitable for you.

Let’s take a look!

Table of Contents

What is a Wood Lathe?

First things first, metal lathes and wood lathes are really not interchangeable. Where many tools can handle both materials, lathes are not typically designed like that. Metal lathes usually are not made to handle wood very well and vice versa. The thing is, metal lathes are more complicated to use overall so if you’re just working with wood, stick to a wood lathe.

Wood lathes are specifically designed for wood, as the name implies. You attach your wood piece to the spindles or the leg, however it is designed, and flip the machine one. A wood lathe will turn the wood and allow you to work with it.

You can use a wood lathe to hold and move your wood piece while you sand, cut, drill, form, or anything else with a piece of wood. The lathe itself will rotate and you will use a cutting tool of some sort against the rotating wood to complete your purpose.

These machines are specifically made for wood. The power and the build of the machine cannot typically handle materials that are not wood. If you try to put a hard or heavy material like metal on a wood lathe, it won’t work well and you might even ruin your lathe in the end.

These lathes are simple because their job for working with wood is pretty simple. A wood lathe uses a system comparable to a pulley and use far less power because they are working with wood alone.

What is a Metal Lathe?

Now, when you take a look at a metal lathe, it is a far more complex machine. Some metal lathes might be able to handle wood but it’s not typically designed to do so. In fact, it probably isn’t even worth messing with because these lathes are far more complex in style and will take a lot of extra effort to not really work with wood like you want it to.

Much like the name might suggest, a metal lathe is designed to work with heavy or challenging materials like metal. These are packed with power, substantially more power than what you see from a wood lathe. These machines are actually described as aggressive.

They have to be aggressive because they are intended to work with metals like aluminum, iron, and steel so they require far more effort and power to do so. With a metal lathe, you can use the machine to help you cut, mold, and form these metal materials.

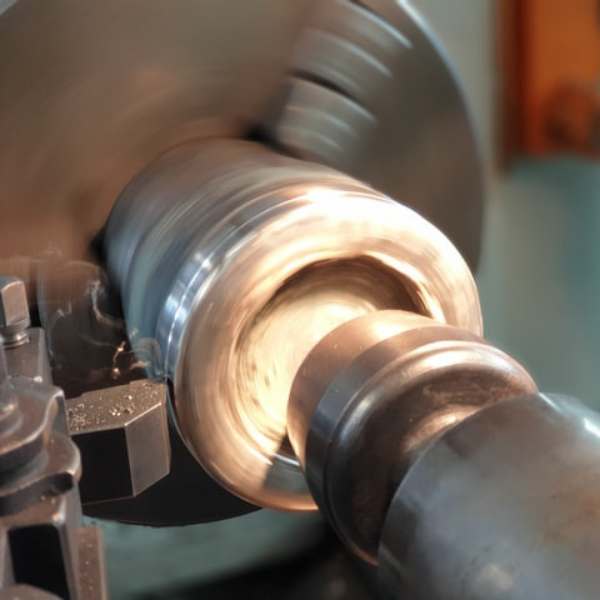

The metal lathe uses a rotating mount that secures the metal and can move it about. The cutting tool used is typically part of the machine and it presses against the metal as you work to cut or form as needed while the machine works.

Metal lathes do support wood when needed but if you have a wood lathe, we recommend sticking to that for wood. However, in a pinch, it will work fine for wood and metal.

Wood Lathe Vs. Metal Lathe – A Complete Comparison

Now that you know what these machines are, let’s compare them side by side and see just how different they really are. In this part of our guide, we will discuss the different parts of these tools and what is different about them so you can see just how differently they really are made.

Power

One of the most substantial differences between a wood lathe and metal lathe is that they have far different power levels. Understandably so, because it requires more power to work with metal.

The average level of power for wood lathes ranges anywhere from 3/4 to 2 HP for a full-sized lathe. The power can be even less if you are looking at a mini or midi wood lathe in comparison. 2 HP is the highest you will typically see here but it is possible that a wood lathe might have more power, it’s just not common.

The motor on a metal lathe can vary considerably as well and there is a broad range in reality. Motors can be as low as 1/8 of a horsepower for small metal lathes but it is a different type of motor than a wood lathe.

On the same note, most large metal lathes have motors that are 2-3 HP on average.

Speed

The speeds can vary on these machines and while the overall speed might be comparable between the two but the metal lathes might also amp up the speed. The speed functionality will mostly be for the needs of the worker using the machines and not for the material itself.

On a wood lathe, you can usually just turn a dial to reduce or raise speed and it won’t affect the work you’re doing directly. It might take time for the adjustment to reflect and you will probably halt work while the speed is adjusted by your hands and by the machine.

However, on a metal lathe, you might be able to work with different speeds at one time. When you turn the speed dial, your results are instant and it happens quick and easy. You won’t have to stop work while you wait for the speed or even to look at the speed in most cases.

Tool Rest

If you are familiar at all with a lathe, some wood lathes have a tool rest while others require handheld tools. It is the same for a metal lathe but it can handle more positions and more tools in most cases.

A tool rest allows you to place your tool and adjust angle quickly and easily. It’s safe because your tool is held securely by the rest, rather than jeopardizing your fingers and risking a slip of your hand or the tool while you work.

The tool rest on a wood lathe is fairly manual and you may have to stop process to adjust or change the rest positioning and such. Some wood lathes don’t even have a rest and some can hold up to 4 tools.

On a metal lathe, there is almost always a tools rest and it typically is a four position tool rest that has four tools. You can switch tools while the process is going and it is safe to do so and won’t harm your project in any way. Switching tools and positions is easy. Keep in mind that the cutting tool is hardened and often attached to the machine on a metal lathe.

How are Wood and Metal Lathes Similar?

Wood lathes and metal lathes are very similar simply in how they operate. They both use a central attachment to turn a material so that you can work with the material to cut, form, and so on.

The overall design and operation of the machines is nearly identical. The concept is the same between the two. However, if you’re looking for similarities, this is about where it ends.

What are the Primary Differences Between a Wood Lathe and Metal Lathe?

Understanding the differences between these two tools is essential because they are built for different purposes. A metal lathe might be considered more versatile because it can handle wood or metal, although it is best for metal.

Here are the noteworthy differences for you to keep in mind.

- Wood lathes are designed for wood and metal lathes are designed for metal but can work for wood

- Wood lathes are much smaller than metal lathes

- Metal lathes are more complex to use

- Wood lathes cost quite a bit less than metal lathes

If you compare the cost of these two machines, you will find that metal lathes typically cost quite a bit more overall. A high-end wood lathe will cost somewhere around $2,500 but you can also find a lot of wood lathes that are closer to $500 as well.

When it comes to a metal lathe, your bottom price is probably going to be around $2,500 and you will most likely not find a metal lathe for much less and rarely under $1,000.

Recommendations

Here are our top recommendations for each type of lathe to give you an idea of where to start.

1. Wood Lathe: Grizzly Industrial Wood Lathe

This full-sized wood lathe is made with solid cast iron. Notice it is not overly huge and the wood fits between a 16 x 46 center. Speeds range from 600-2400 RPM. Your tool rest is simple and precise but easy to move and the controls are all right there and simple to operate.

2. Metal Lathe: Techntongda Precision Metal Lathe

This metal lathe is a small, basic metal lathe and considered to be a benchtop version. Notice the very different design and build compared to the Grizzly. Freestanding metal lathes get very large overall.

This lathe uses a smaller motor because it is a small lathe. It ranges with 50-3500 RPM, and the cutting tool is attached. The speed can easily be adjusted at any time and you have a precise tool rest as well, with an enclosed motor.

Conclusion

When it comes to comparing a wood lathe and metal lathe, they are both designed with similar concepts. The lathe in general is made to have a rotating piece to hold the material. From there, the capabilities and even design vary quite a bit as the wood lathe is designed for wood and the metal lathe is designed for metal.

Best Selling Wood Lathes on Amazon:

- Attack workpieces up to 18 inches long and 12 inches wide

- Switch between five different speeds: 520, 900, 1400, 2150, or 3400 RPM

- Includes 3-1/8 inch faceplate for turning bowls, cups and other non-spindle workpieces

- MT2 tailstock and headstock tapers allow for compatibility with a wide variety of lathe accessories

- Features a 4.5A motor, an MT2 headstock spur center, an MT2 tailstock live center, an 8-inch tool rest, and an onboard accessory holder

- Perfect for turning pens, bowls, cups, chess pieces, and other small workpieces

- Features an 8-inch swing over the bed and a 13-inch distance between centers

- Soft-start 3.2-amp motor starts gradually to prevent damage to the motor and maximize safety

- Adjust the variable speed anywhere from 750 to 3200 RPM

- Includes a 2.3-inch face plate, an MT1 spindle and tailstock taper, two interchangeable tool rests, and a two-year warranty

Best Selling Metal Lathes on Amazon:

- Widely Used: Our metal lathe machine, measuring 8.3'' x 29.5'', is perfect for processing precision parts and models. It has a wide range of turning pitches that can create 24 different kinds of threads, including 14 metric system (ranging from 0.3-3mm) and 10 imperial system (ranging from 10-44 TPI) threads.

- Built to Last: Our power metal lathes are built to last with high-quality HT200 cast iron. They come equipped with wear-resistant and strong metal gears and aluminum alloy handwheels, ensuring a longer service life.

- 750W Brushless Motor: Our benchtop metal lathe features a 750W brushless motor that provides more power and avoids the need for brush replacements, saving time and effort.

- Continuously Variable: Features a spindle that can turn in both forward and reverse directions, with two-speed options: a high gear of 100-2500 rpm and a low gear of 50-1250 rpm. It also has intelligent electric speed controls and a digital display, allowing for accurate speed adjustments and making your work easier.

- Security Comes First: Our metal lathe machine has multiple security features in case of emergency, ensuring operator security. These include an emergency stop switch, overload protection, chuck cover power off switch, pulley set housing power off switch, and a main control panel security switch.

- Mini Yet Powerful: Measuring only 40x14 in., this mini metal lathe by Creworks packs a punch with its 1100W brushless motor, making it ideal for tackling small to medium metalworking projects. It provides an 8.7 in. swing over bed and 23.6 in. distance between its centers with a 1.5 in. spindle bore.

- Complete Control: The mini metalworking machine's rotational speed can be set from 0 to 3000 rpm and monitored through the real-time digital display. The well-crafted head and tailstocks, large through-hole, and 4-way tool post also contribute to providing greater control of your work.

- Precise Engineering: Ideal for professionals, this benchtop mini metal lathe's high-precision 5-inch 3-jaw chuck handles both square and round objects with equal aplomb. Its granular precision is especially useful for jobs requiring high accuracy such as threading.

- Ultra Sturdy & Safe: The robust cast iron construction ensures a long service life and superior corrosion resistance. The transparent chuck guard protects you from swarf or broken tools while also permitting visibility into the point of operation.

- Wide Application: Tailored for precision tasks, this mini woodworking lathe effortlessly handles turning, drilling, threading, and cutting. Its capabilities extend to various materials, including wood, plastics, brass, aluminum, and more!